- PERFECT AIR FILTER

- GA-SERIES / VF-500 / PF-14 (New)

- Compressed air oil-water separator

- Remove moisture 99.99% in the compressed air,

Remove thespray phenomenon of air gun,

Extend the lifecycle of equipment.

Usage of Air Filter

- Eliminate the oil/moisture and impurities in the compressed air made in the compressor.

- Resolve problems due to phenomenon of nebulization and dew condensation of air gun (Especially, during the summer time)

- By improving the quality of compressed air to be used in the machine tool, extend the life span

- Able to apply to various fields such as machine tool, air gun, small type compressor for dental (GA-SERIES)

- Able to use in industrial fields that high precision - clean air is required such as food processing line, powder coating and semi-conductor etc.

- Absolutely follow the recommended working pressure. (*GA-series : within 2-10bar, *VF-500 : within 2-8bar, *PF-14 : within 3-7bar.)

Features of Air Filter

- Eliminate the condensation water 99.99% in the compressed air

- Able to use semi-permanently (GA-SERIES)

- All in one type filter in combination with centrifugation type and element cartridge replacement type (RF-SERIES)

- Processing surface with anodizing, there are coating effects and beautiful appearance

- Piping size per capacity GA SERIES : 4 sizes (PT 1/8”, 1/4”. 1/2”, 1”)

- Piping size per capacity RF-SERIES : 3 sizes (PT 1/4”, 1/2”, 1”)

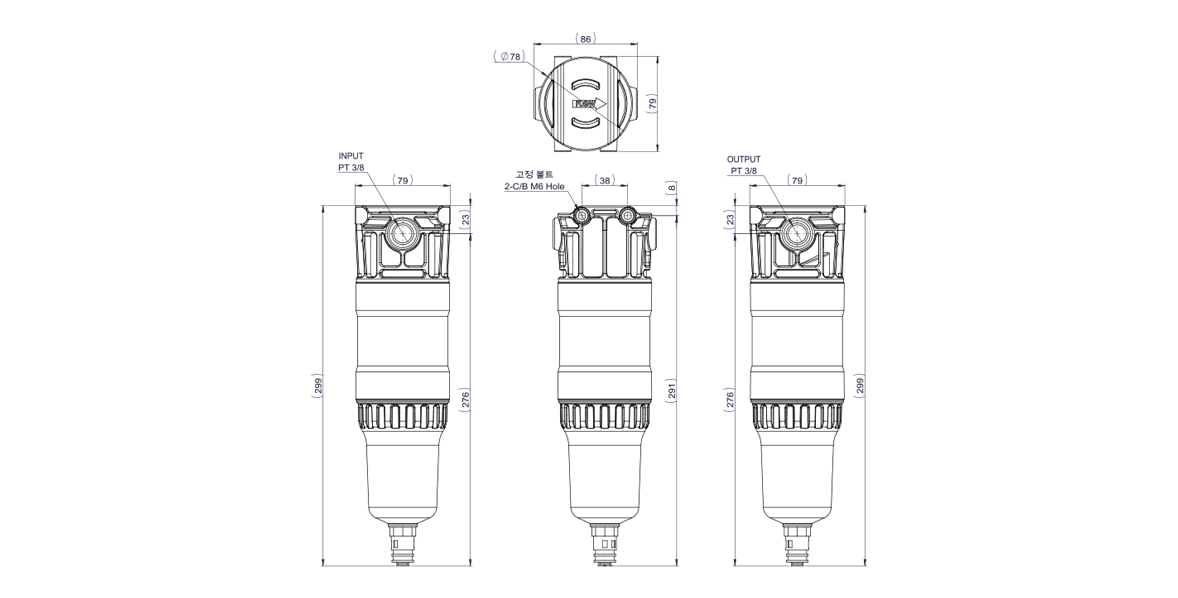

- Piping size per capacity VF-500 : PT-3/8

- GA-SERIES & VF-500 Filtration: Higher than 1-3㎛ / RF-SERIES Filtration: Higher than 0.01㎛

- More economical use of GA-series performance through injection production.

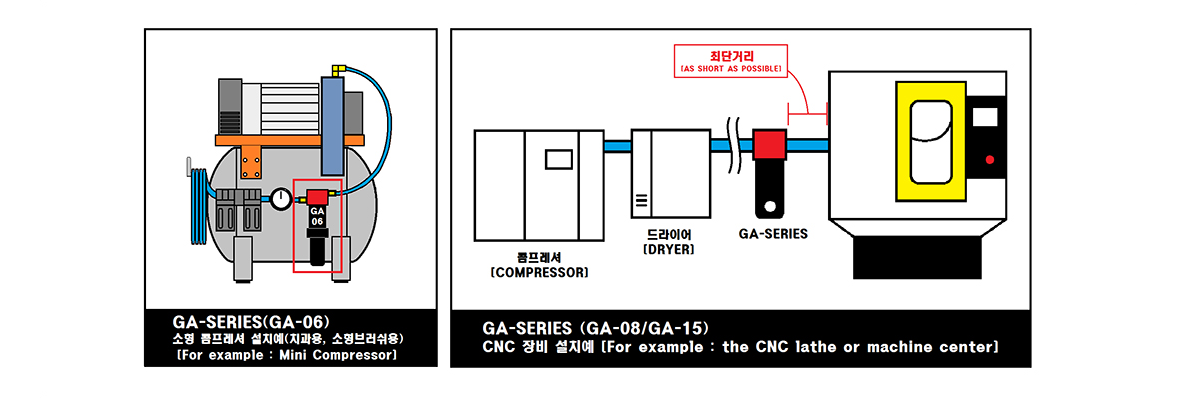

Application Example

Video

PF-14 Application Example

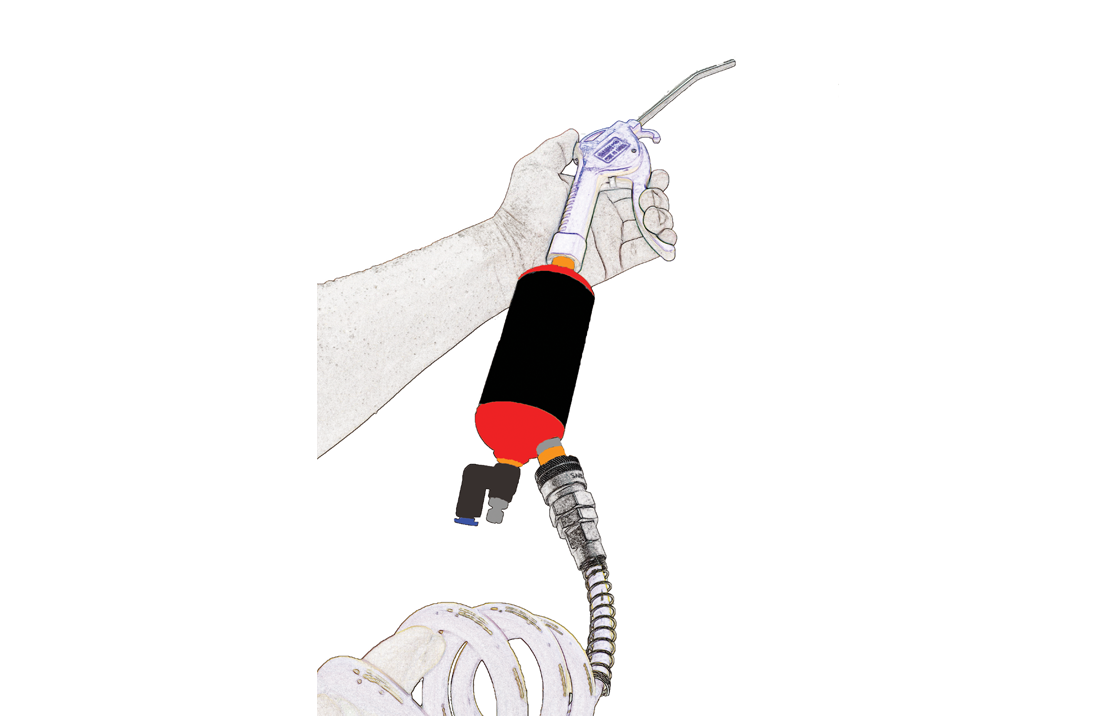

Air gun application example

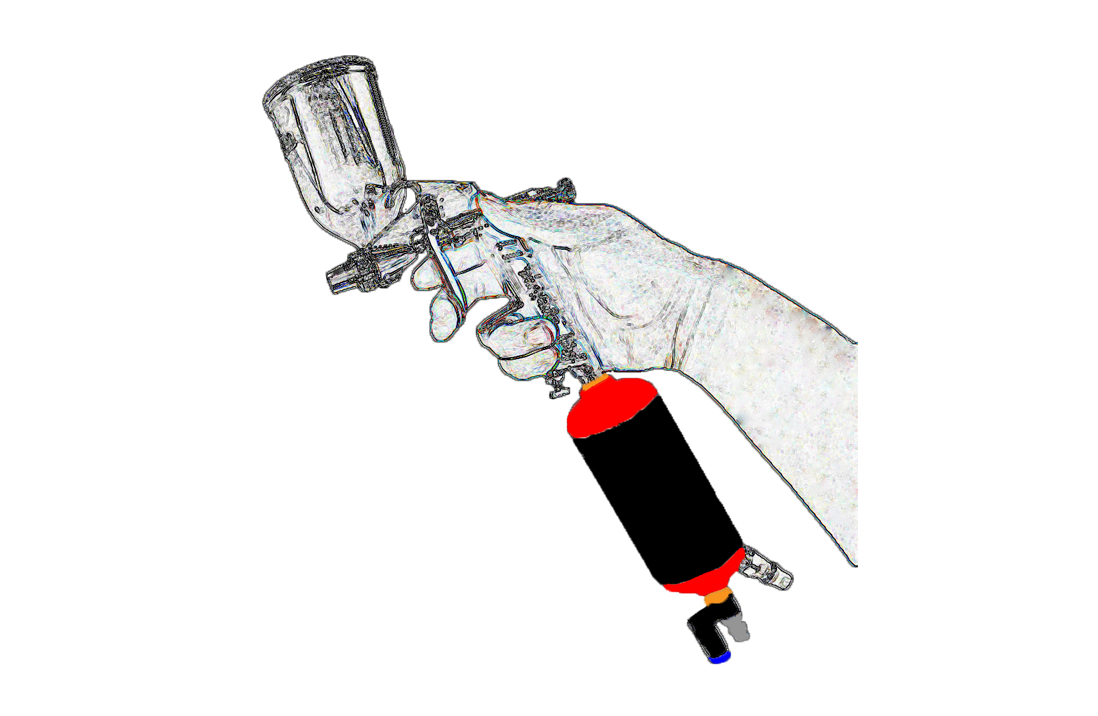

Air spray gun application example

PF-14 Video

GA-Series, VF-500 Air Filter Specification

| Model | GA-06 | GA-07 | GA-08 | GA-15 | GA-25 | VF-500 |

|---|---|---|---|---|---|---|

| Max.Flow rate [Nℓ / min] | 100 | 150 | 350 | 700 | 1,500 | 500 |

| Pressure drop [bar(kgf/cm2)] | 1.0~2.0 (1.01~2.03) | |||||

| Working pressure [bar(kgf/cm2)] | 2.0~10.0 (2.02~10.2) | 2.0~8.0 | ||||

| Max.pressure [bar(kgf/cm2)] | 15.0 (15.3) | |||||

| Fluid temperature [℃] | 0~60 | |||||

| Min.Filtration range | More than 1~3 ㎛ | |||||

| Drain output Dia. [mm] | One touch hose nipple Ø6mm | |||||

| Drain type | Semi-auto drain | Auto drain (Can be drained manually) | ||||

| In/Output Dia. [PT] | 1/8 | 1/4 | 1/4 | 1/2 | 1 | 3/8 |

| Weight [kg] | 0.4 | 0.6 | 1.0 | 1.7 | 4.5 | 0.6 |

※ Specifications and sizes of the product can be changed without prior notice according to the product development process of the head-quarter.

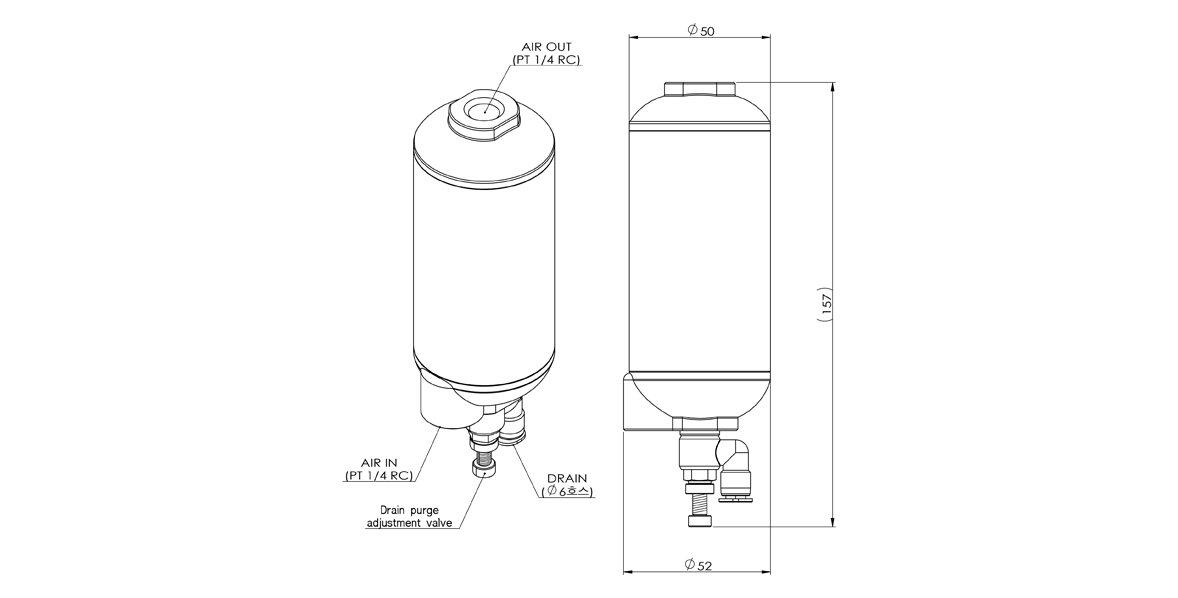

PF-14 Air Filter Specification

| MODEL | PF-14 |

|---|---|

| Operation Pressure | 3-7 kgf/cm2 |

| Operation Flow rate | ~450 LPM 이내 |

| Operation Temperature | 0~60 ℃ 이내 |

| Pressure Drop | 0.5~1.0 kgf/cm2 |

| Drain type | 수동 |

| Filtration | 응축수 95% 이상 제거, 1-3㎛ 이상 제거 |

| Weight | 약 240g |

※ These measurements were measured under our test conditions. And they depend on various conditions.

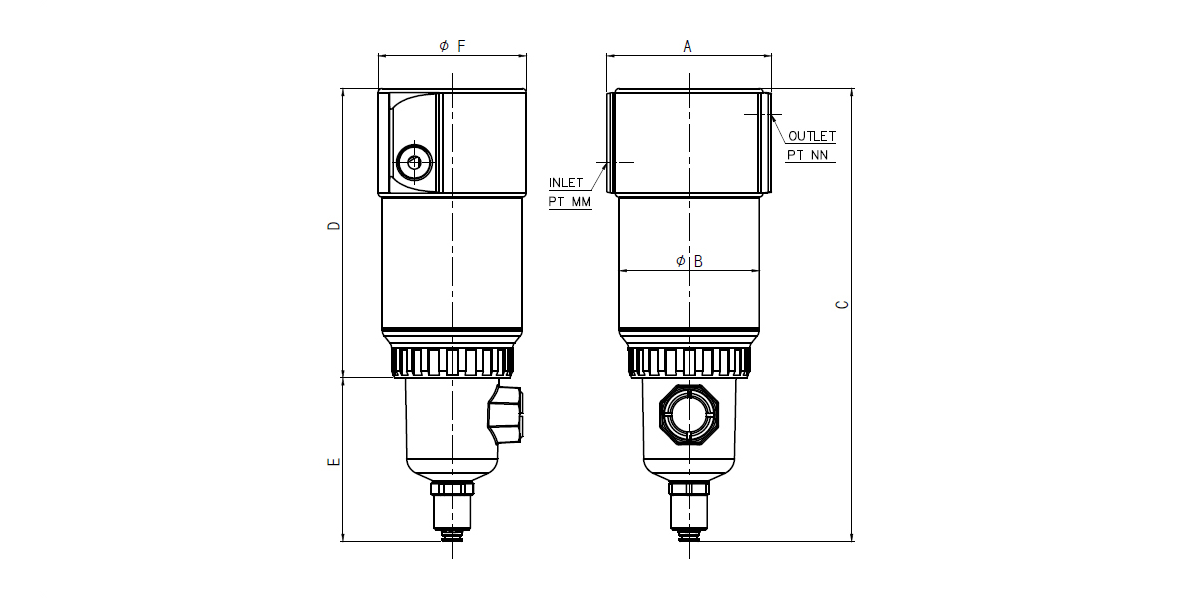

Air Filter Size (GA-SERIES)

| MODEL | GA-06 | GA-07 | GA-08 | GA-15 | GA-25 |

|---|---|---|---|---|---|

| A mm | 56 | 64 | 84 | 100 | 144 |

| B mm | 48 | 55 | 72 | 85 | 120 |

| C mm | 212.5 | 225.7 | 265 | 276 | 408 |

| D mm | 133 | 134 | 165 | 176 | 308 |

| E mm | 79.5 | 91.7 | 100 | 100 | 100 |

| F mm | 52 | 60 | 76 | 90 | 130 |

| MM | 1/8 | 1/8 | 1/4 | 1/2 | 1 |

| NN | 1/8 | 1/8 | 1/4 | 1/2 | 1 |

※ These specifications and dimensions are for reference only.

And these are subject to change without prior notice depending on the product development process of our company.

※ If processing of the assembly is required, be sure to check the actual size of the product for the relevant.

Outside View (GA-SERIES)

Outside View (VF-500)

Outside View (PF-14)

Precautions of Air Filter

- Observe working pressure. [Recommended pressure GA-SERIES : Within 2~10 BAR]

- Observe working pressure. [Recommended pressure VF-500 : Within 2~8 BAR]

- Observe working pressure. [Recommended pressure PF-14 : Within 3~7 BAR]

- Recommended air pressure: 3~6kg/㎠

- Recommended air temperature: 0~60℃

- Recommended operating time: 8 hour/1 day (Warranty period : 12 months from date of purchase)

- It is used for the purpose of filtering industrial compressed air discharged from compressor.

- Never install or use this product near the worker’s working radius or pathway, or near the body.

- This product is an industrial pneumatic device.

Never use to food or any other way that directly affects the human body.